Oee Formula In Excel

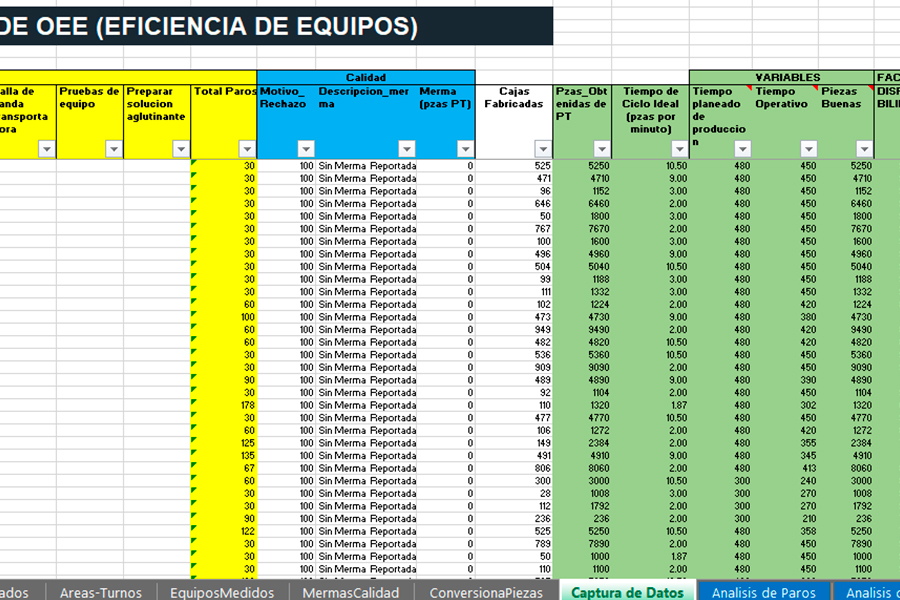

Oee Formula In Excel - Oee (overall equipment effectiveness) is a “best practices” metric that identifies the percentage of planned production time that is truly productive. Oee is an acronym that stands for overall equipment effectiveness and is a metric measures the overall efficiency of a machine or group of machines. Learn how to calculate oee to gain insight into the effectiveness of your manufacturing process and improve production. Overall equipment effectiveness is a maintenance kpi that measures an asset’s level of productivity. Learn about the three oee factors: Oee is a combination of three factors that tell you. It is a valuable measure of a machine's. Overall equipment effectiveness[1] (oee) is a measure of how well a manufacturing equipment is utilized compared to its full potential, during the periods when it is scheduled to run. Overall equipment effectiveness is a key metric used within the manufacturing industry to assess how well machines are performing. Oee (overall equipment effectiveness) is the gold standard for measuring manufacturing productivity. Availability, performance, and quality and how the related losses impact manufacturing productivity. Oee (overall equipment effectiveness) is a “best practices” metric that identifies the percentage of planned production time that is truly productive. Overall equipment effectiveness[1] (oee) is a measure of how well a manufacturing equipment is utilized compared to its full potential, during the periods when it is scheduled. Oee (overall equipment effectiveness) is the gold standard for measuring manufacturing productivity. It is a valuable measure of a machine's. An oee score of 100% represents perfect. Overall equipment effectiveness[1] (oee) is a measure of how well a manufacturing equipment is utilized compared to its full potential, during the periods when it is scheduled to run. Oee is a combination. An oee score of 100% represents perfect. Learn about the three oee factors: Availability, performance, and quality and how the related losses impact manufacturing productivity. Learn how to calculate oee to gain insight into the effectiveness of your manufacturing process and improve production. Oee is an acronym that stands for overall equipment effectiveness and is a metric measures the overall. Availability, performance, and quality and how the related losses impact manufacturing productivity. Oee is an acronym that stands for overall equipment effectiveness and is a metric measures the overall efficiency of a machine or group of machines. At its core, overall equipment effectiveness (oee) is a powerful metric that measures how effectively a manufacturing operation utilizes its resources. An oee. Oee (overall equipment effectiveness) is a “best practices” metric that identifies the percentage of planned production time that is truly productive. Overall equipment effectiveness is a key metric used within the manufacturing industry to assess how well machines are performing. Overall equipment effectiveness is a maintenance kpi that measures an asset’s level of productivity. Availability, performance, and quality and how. Understand the six big losses in manufacturing and how tpm and oee programs reduce them to improve productivity. Oee is a combination of three factors that tell you. An oee score of 100% represents perfect. Oee (overall equipment effectiveness) is a “best practices” metric that identifies the percentage of planned production time that is truly productive. Oee (overall equipment effectiveness). Learn how to calculate oee to gain insight into the effectiveness of your manufacturing process and improve production. Oee is a combination of three factors that tell you. Understand the six big losses in manufacturing and how tpm and oee programs reduce them to improve productivity. At its core, overall equipment effectiveness (oee) is a powerful metric that measures how. Understand the six big losses in manufacturing and how tpm and oee programs reduce them to improve productivity. Oee is a combination of three factors that tell you. Oee (overall equipment effectiveness) is a “best practices” metric that identifies the percentage of planned production time that is truly productive. Oee (overall equipment effectiveness) is the gold standard for measuring manufacturing. Understand the six big losses in manufacturing and how tpm and oee programs reduce them to improve productivity. Learn how to calculate oee to gain insight into the effectiveness of your manufacturing process and improve production. An oee score of 100% represents perfect. Oee (overall equipment effectiveness) is a “best practices” metric that identifies the percentage of planned production time. Oee is an acronym that stands for overall equipment effectiveness and is a metric measures the overall efficiency of a machine or group of machines. Learn about the three oee factors: Overall equipment effectiveness is a key metric used within the manufacturing industry to assess how well machines are performing. Understand the six big losses in manufacturing and how tpm.Plantilla OEE excel Calidad Total Para Sus Procesos

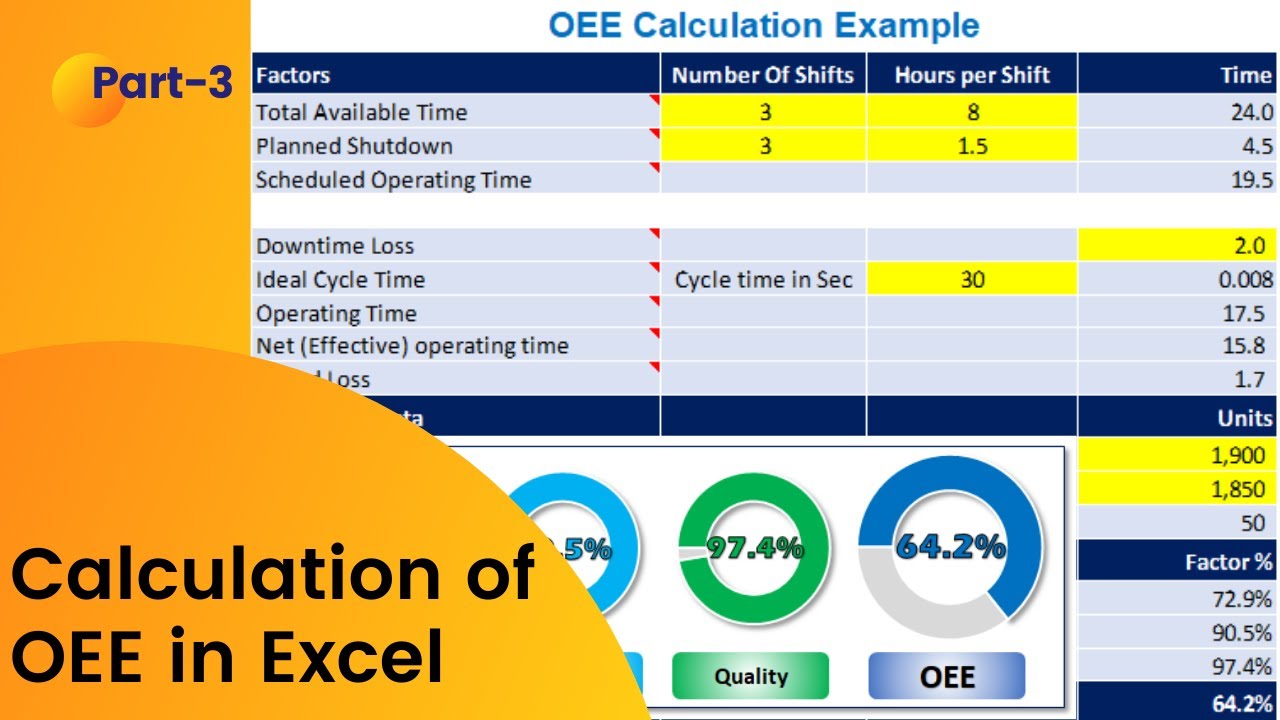

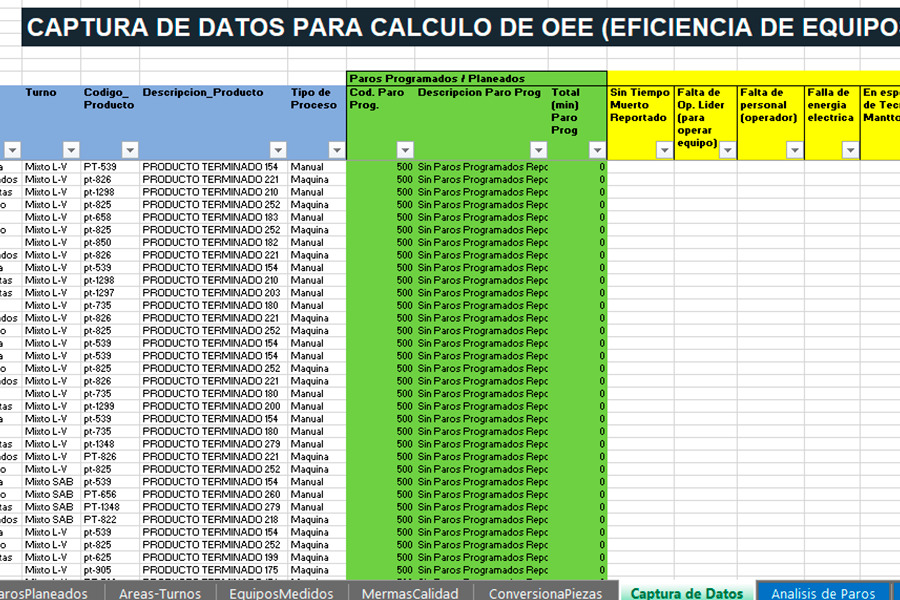

OEE in Excel Sheet OEE Excel Formulas How to Calculate OEE

Oee Excel Template

Oee Excel Template

Oee Excel Template

Cálculo OEE Plantilla excel ADN Lean

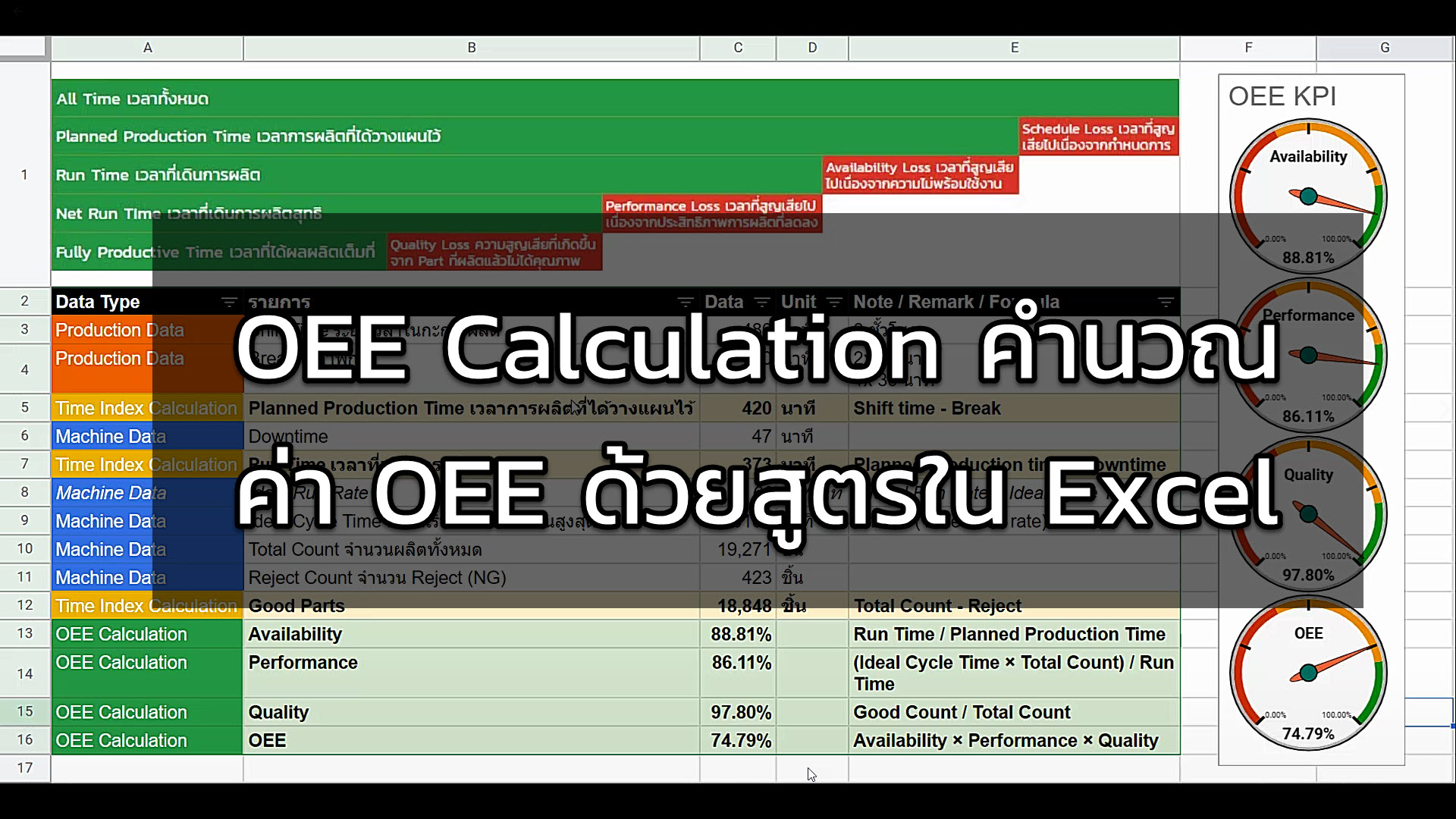

OEE Calculation คำนวณค่า OEE ด้วยสูตรใน Excel คำนวณ A P Q และ OEE

Oee Excel Template

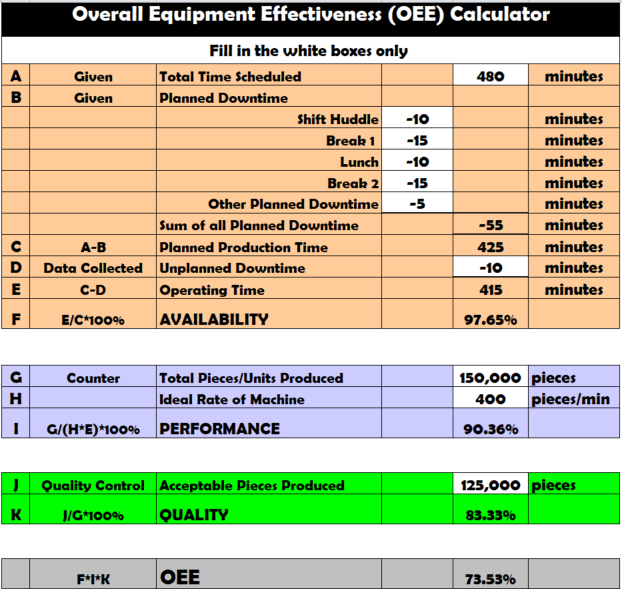

Como Se Calcula El Oee at Elijah Octoman blog

Plantilla OEE excel Calidad Total Para Sus Procesos

Related Post: