Machining Cost Calculation Excel

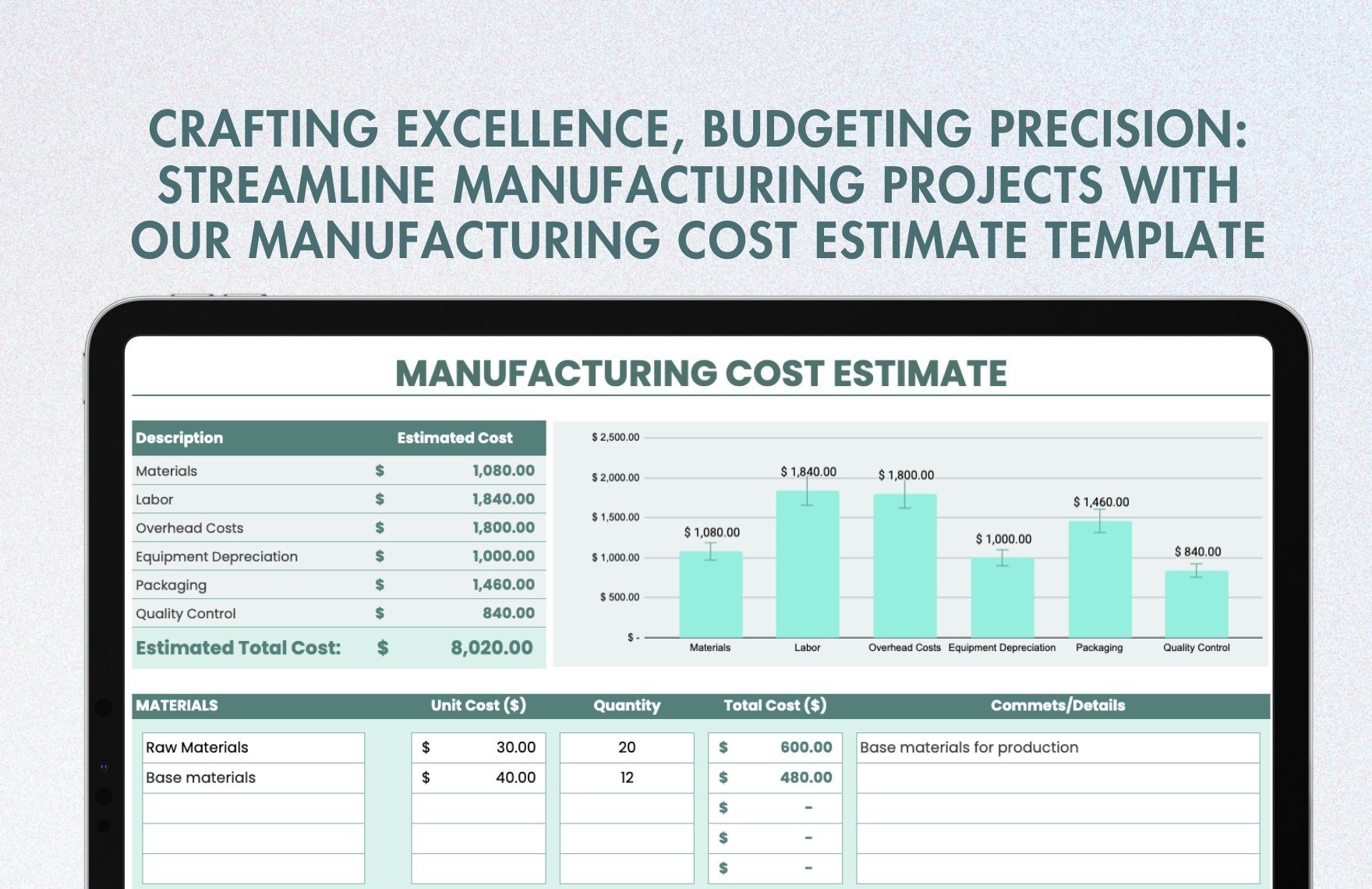

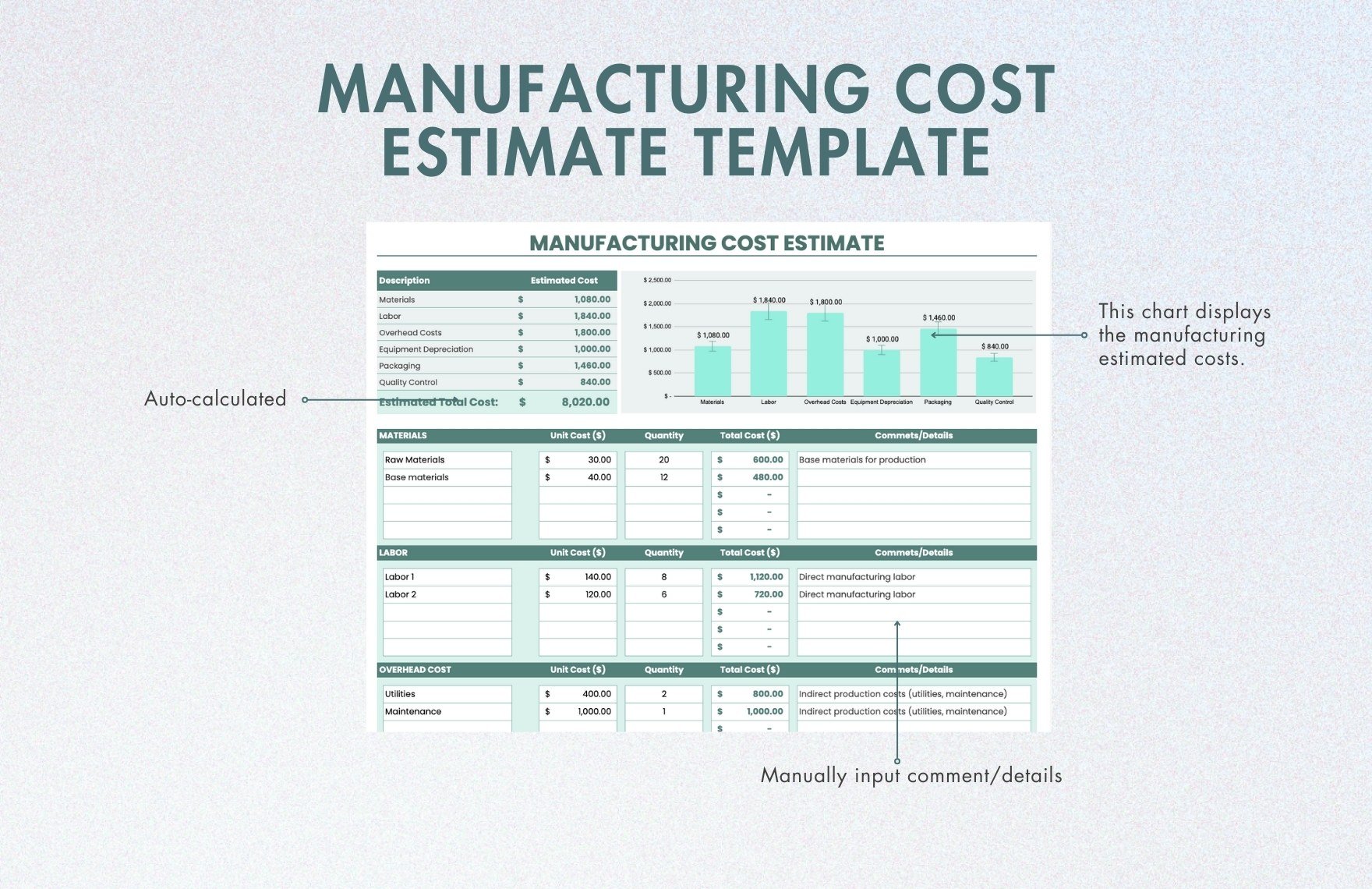

Machining Cost Calculation Excel - Machining is a manufacturing process used in workshops to shape or remove material from a workpiece using cutting tools. Machining is a subtractive manufacturing process that involves the use of cutting tools, discs, abrasive wheels, and more to remove excess material from a workpiece. This process is essential for creating. Machine shops and machinists use. Machinists in machine shops use mills, lathes, and other equipment to. Machining is a core manufacturing process that involves cutting material from a workpiece to create a specific shape and size. At able manufacturing, technical knowledge, ingenuity, and years of practical application and experience are ready to meet your production, turning, machining, and grinding requirements. An overview of nine types of machining processes including turning, drilling, milling, and more. Machining is a prototyping and manufacturing process that creates the desired final shape by removing unwanted material from a larger piece of material. Machining is the process used to remove material, typically metal, to create parts for machines, tools, transportation, and more. Machining is a manufacturing process used in workshops to shape or remove material from a workpiece using cutting tools. Machining is a manufacturing process where a desired shape or part is created using the controlled removal of material, most often metal, from a larger piece of raw material by cutting. An overview of nine types of machining processes including turning,. Machinists in machine shops use mills, lathes, and other equipment to. At able manufacturing, technical knowledge, ingenuity, and years of practical application and experience are ready to meet your production, turning, machining, and grinding requirements. Machining is a prototyping and manufacturing process that creates the desired final shape by removing unwanted material from a larger piece of material. Machining is. Machining is the process used to remove material, typically metal, to create parts for machines, tools, transportation, and more. At able manufacturing, technical knowledge, ingenuity, and years of practical application and experience are ready to meet your production, turning, machining, and grinding requirements. Machining is a manufacturing process used in workshops to shape or remove material from a workpiece using. Machining is the precise process of removing metal or other materials to make a wide variety of useful tools and parts. This process is essential for creating. Machining is the process used to remove material, typically metal, to create parts for machines, tools, transportation, and more. Machining is a core manufacturing process that involves cutting material from a workpiece to. Machining is a subtractive manufacturing process that involves the use of cutting tools, discs, abrasive wheels, and more to remove excess material from a workpiece. It involves cutting, shaping, or finishing materials. An overview of nine types of machining processes including turning, drilling, milling, and more. Machine shops and machinists use. Machining is the precise process of removing metal or. At able manufacturing, technical knowledge, ingenuity, and years of practical application and experience are ready to meet your production, turning, machining, and grinding requirements. Machining is a manufacturing process used in workshops to shape or remove material from a workpiece using cutting tools. Machining is a core manufacturing process that involves cutting material from a workpiece to create a specific. It involves cutting, shaping, or finishing materials. Machining is a prototyping and manufacturing process that creates the desired final shape by removing unwanted material from a larger piece of material. This process is essential for creating. Machining is the process used to remove material, typically metal, to create parts for machines, tools, transportation, and more. Machining is a manufacturing process. At able manufacturing, technical knowledge, ingenuity, and years of practical application and experience are ready to meet your production, turning, machining, and grinding requirements. Machine shops and machinists use. This process is essential for creating. Machining is a core manufacturing process that involves cutting material from a workpiece to create a specific shape and size. Machining is the process used. An overview of nine types of machining processes including turning, drilling, milling, and more. Machining is the precise process of removing metal or other materials to make a wide variety of useful tools and parts. Machining is a manufacturing process used in workshops to shape or remove material from a workpiece using cutting tools. Machining is a manufacturing process where. Machinists in machine shops use mills, lathes, and other equipment to. Machine shops and machinists use. Machining is a subtractive manufacturing process that involves the use of cutting tools, discs, abrasive wheels, and more to remove excess material from a workpiece. Machining is a manufacturing process used in workshops to shape or remove material from a workpiece using cutting tools..Manufacturing Cost Estimate Template in Excel, Google Sheets Download

Manufacturing Cost Estimation Excel at Ruby Huntley blog

Manufacturing Cost Estimation Excel at Ruby Huntley blog

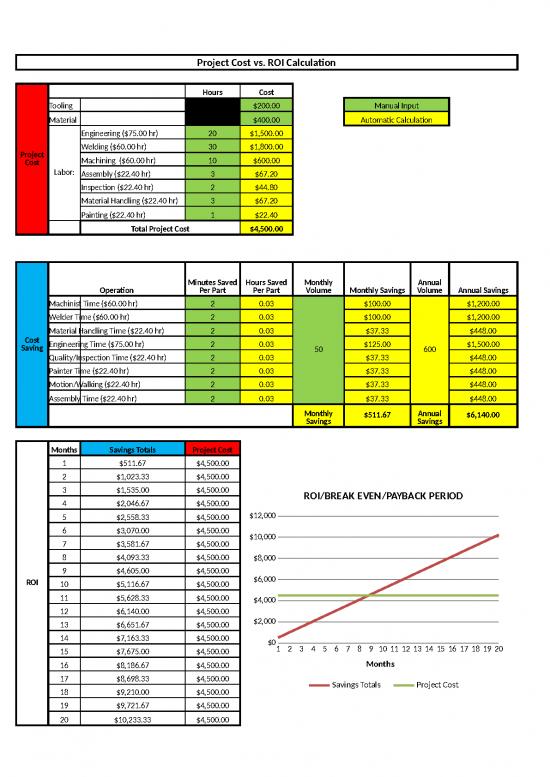

Free Manufacturing Cost Analysis Templates For Google Sheets And

Looking Good Tips About Manufacturing Cost Accounting Templates Excel

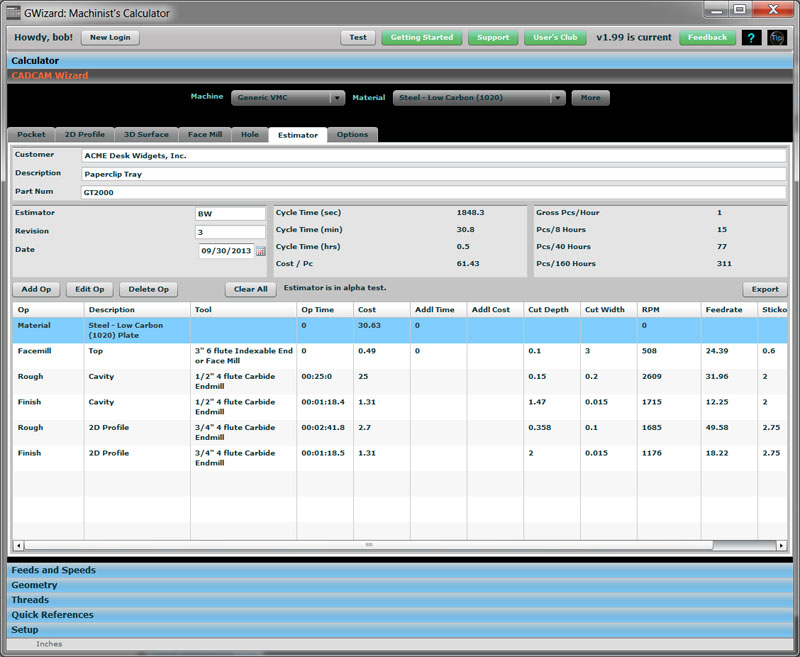

2 Machining Cost Calculation Excel Files Download Free Collection Files

Machine Shop Estimating Spreadsheet Spreadsheet Downloa machine shop

Manufacturing Cost Estimate Template in Excel, Google Sheets Download

Injection Molding Product Cost Calculation Sheet Efficient Estimation

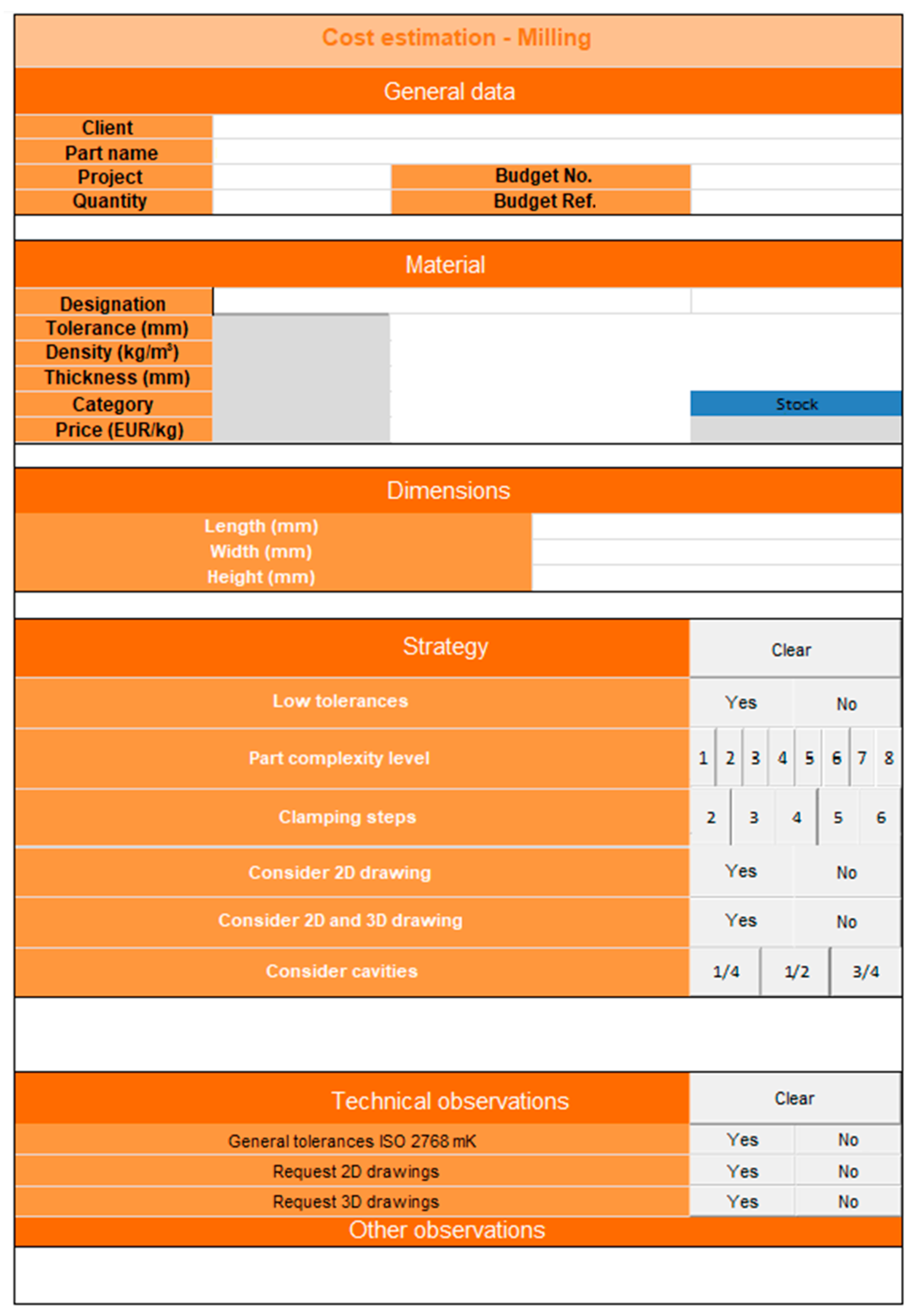

BuildUp an Economical Tool for Machining Operations Cost Estimation

Related Post: